The whistling of a foil often comes from square or splintered trailing edges.

Once in the water and at speed, this creates turbulent flows along the surfaces of your foil. (Small vortices after the trailing edge cause annoying noises and potentially vibrations at high speeds. The shape of the trailing edge is a major factor in this noise problem.

To dig a little deeper and understand whistling: It’s a fluid dynamics phenomenon called the “Karmen vortex”.

As the fluid flows around the profile, two vortices are generated by the two square corners of the trailing edge. Each vortex is a low-pressure vortex, and tends to form one after the other.

A multitude of vortices, some coming from the top of the trailing edge, others from the bottom, follow one another, creating an oscillating force acting on the trailing edge of the airfoil, and thus a whistling sound.

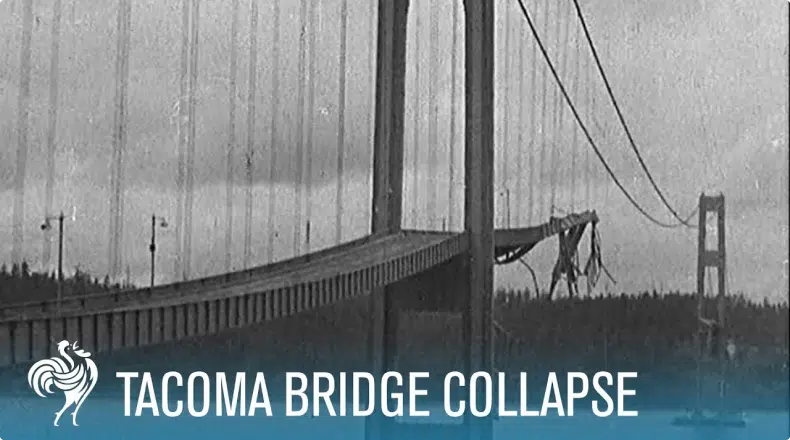

It’s the same phenomenon that makes electric cables whistle overhead, or that caused the Tacoma Bridge to vibrate and then collapse in 1940.

To reduce noise, a commonly used solution is a “Donaldson” trailing edge. This solution was “discovered” in the 1950s by the aeronautical engineer of the same name.

If your foil whistles, the first thing to do is check the trailing edge. If there are any rough spots, you can sand them down with fine sandpaper.

If the trailing edge is smooth, you can check the wing assembly. Make sure that all parts are tight and that there is no play.

If you’ve checked the trailing edge and wing assembly and the whistling still persists, the wing may be defective. In this case, you should contact the manufacturer or dealer for a replacement.

To solve a whistling problem, simply sand the trailing edges very lightly using this method, to obtain laminar flows thanks to a fine, regular trailing edge.

Be sure to identify the bottom surface of your wing or stab, as this is where you’ll be sanding the trailing edge.

Use wide, even strokes. It’s important not to sand too hard to avoid distorting the wing’s profile. Carefully use water-based sandpaper on the front wing and stabilizer, following specific angles and steps.

Start with the coarsest sandpaper (p220) and end with the finest (p1000). The aim is not to make scratches, but to slightly reduce the thickness of the trailing edge. This sanding should be very light and even. The trailing edge should then be caught up with a shim to make the sanding as even as possible.

Sand the trailing edge at a 45° angle with the p240 and the rigid shim, to obtain an even, sloping trailing edge. Move slowly and evenly to avoid distorting the trailing edge. In general, 2 to 6 round-trips are sufficient.

Repeat the operation with a p400, making 2 round trips, and finish by rounding off the last small angle between the surface of the profile and the trailing edge.

Repeat operation 2- with p600-p800

Once you’ve properly sanded the trailing edge of your foil, you should notice a reduction or disappearance of the whistling.

Warnings

It’s important to be careful when sanding the trailing edge of a foil. The edges can be sharp and dangerous.

If you’re not sure how to proceed, it’s best to call in a professional.

Once finished, you’ll probably notice a reduction in vibration and a quieter foil. Caution is essential, as sharp edges can be dangerous.

Always wear work gloves when sanding, and be aware of the associated risks. Anyone who decides to carry out these procedures does so with full knowledge of the risks and under his or her own responsibility.

Before you start, read the warranty policy carefully.

Click & Collect

Secure payment in 3 or 4 instalments

Advice from enthusiasts

Satisfied or refunded

2 to 3-year warranty

Worldwide shipping

Foil and Co., All rights are reserved. ©2024